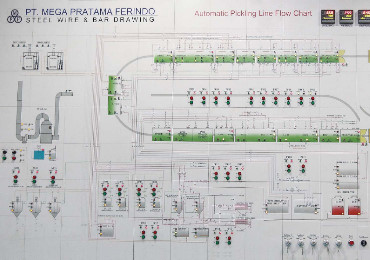

Continuous Pickling Line

1. The Continuous Pickling Line accomplishes the monthly production capacity of 12,000 tons per month, and the sealed tank prevents leakage of the corrosive gas. The main equipment includes tank ( /units), crane (10/units), conveyer for wire rods (1/set), high pressure blow wash (2/sets), column scrubber ( 2/sets), drying system (2/sets), wire rod vibration system (10/sets), hook (10/units), maintenance rail (1/set), other chemical conveying system and heating system.

2. Based on the types of wire rod the process and dipping time are adjustable; the completely automatic apparatus helps to perform with quality assurance.

3. The Continuous Pickling Line is designed and manufactured by I Young Engineering Co., Ltd., Taiwan and is patented in mainland China and Taiwan, which is one of the most advanced auto pickling equipment nowadays.